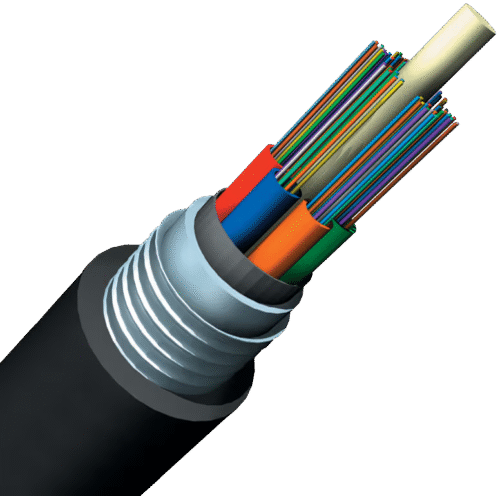

Loose tube cables are the product of choice as the backbone in Outside Plant (OSP) environments. The durable loose tube design offers reliable transmission performance over a broad temperature range. Optical fibers are placed inside filled buffer tubes containing PFM™ gel. The core is constructed by stranding the buffer tubes around a central member using a reverse oscillating lay (ROL). The core is wrapped with flexible strength members covered with a water-blocking tape. A corrugated steel armor is applied and then encased with a black jacket. Rip cords are included under the armor for ease of entry.

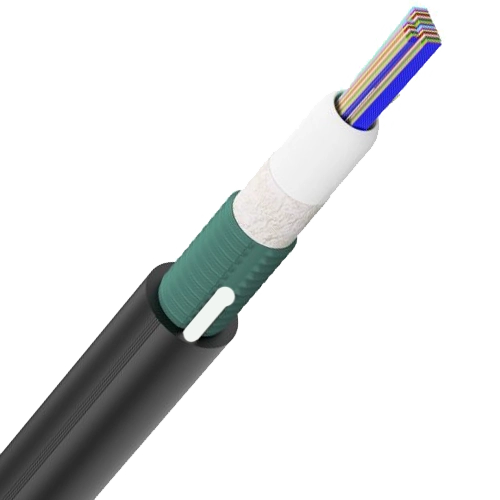

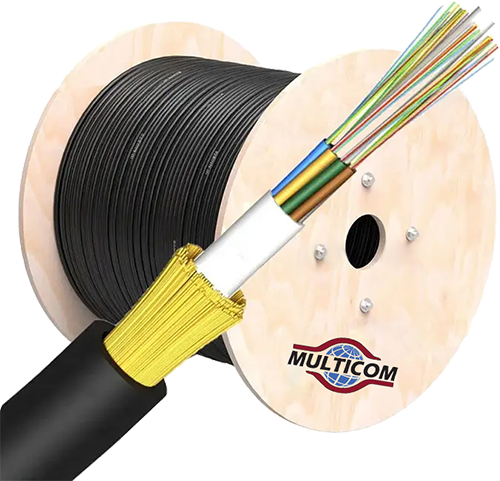

Fiber optic cables must be rigid yet flexible enough to be installed into duct systems. Nanda Technologies can supply a range of fiber optic cables including duct fiber cables. Our duct fiber optic cables are metallic and dielectric cables. The number of fibers is from 2 to 432 fibers. The duct fiber optic cable is with aluminum foil as the moisture barrier layer, aramid, and Kevlar is for tensile strength support. Glass yarn or polyamide is used to prevent rodents.